Your location:home > products > GAS REGULATOR > 627 Series Gas Regulator

627 Series Gas Regulator

627 Series Gas Regulator

- Product Name:627 Series Gas Regulator

- Products:GAS REGULATOR > 627 Series Gas Regulator

|

Technical Parameters

|

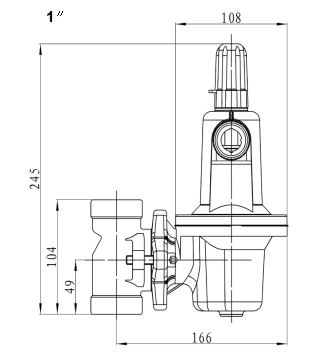

size

See the second page size chart

Pipe diameter

Inlet 1"npt / 2"npt internal threaded connection outlet 1"npt / 2"npt internal thread connection

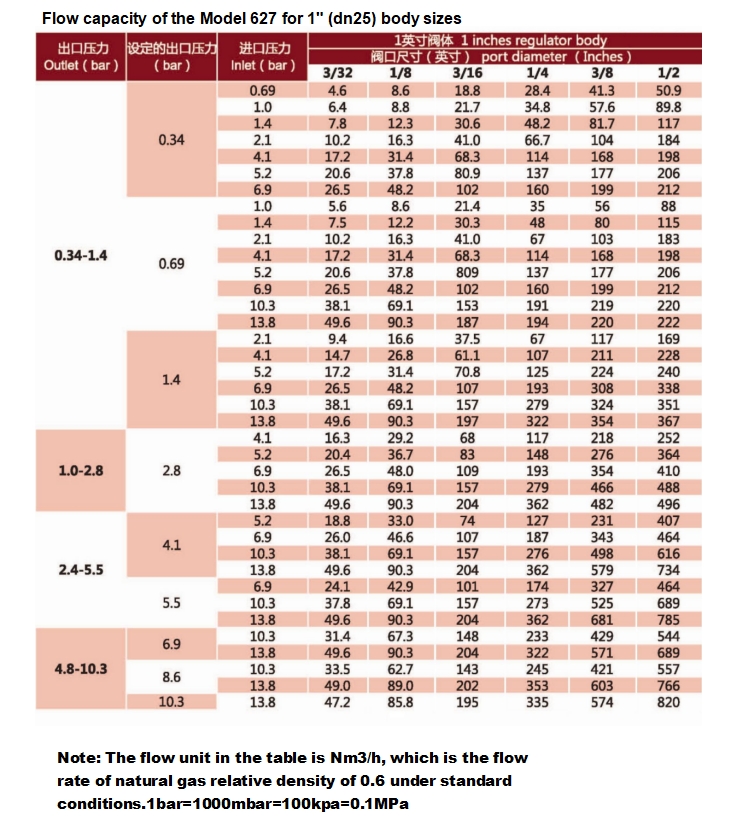

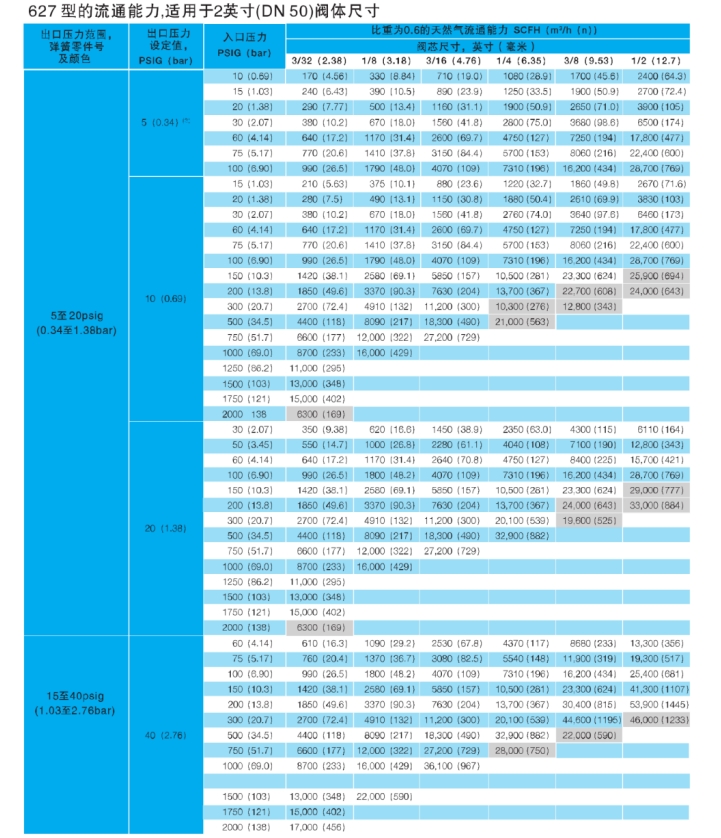

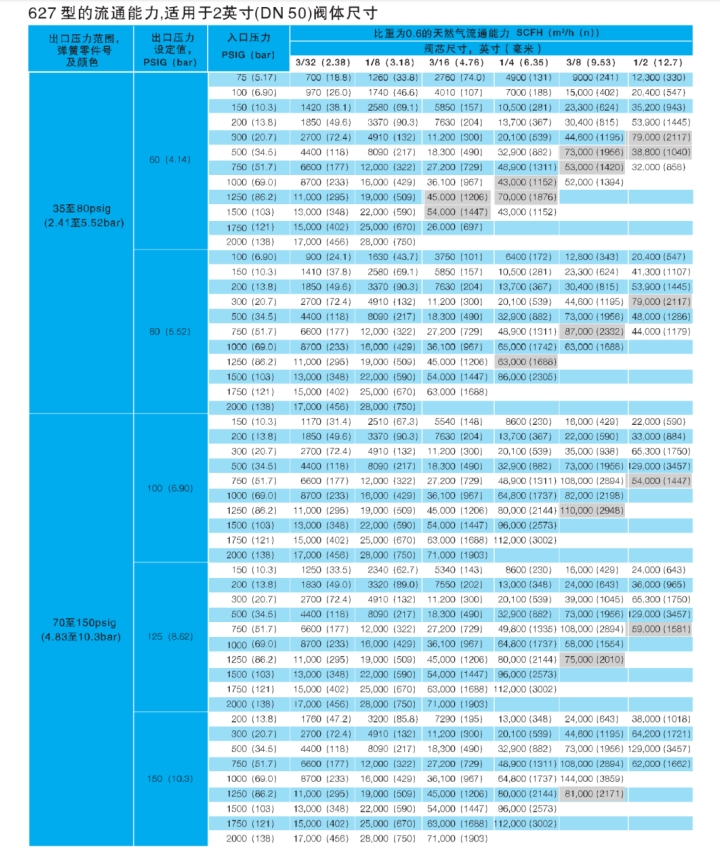

flow

Refer to the third page flow meter

Maximum inlet pressure / P1max 16bar

Export pressure range 0.34~1.4bar

1.0-2.8bar

2.4-5.5bar 4.8-10.3bar

Connection size 1″NPT

2″NPT

Overview

The 627 Series regulator is a direct acting regulator.The utility model has the advantages of simple structure, convenient operation and convenient online maintenance.It belongs to high pressure and small flow regulator.

application

Suitable for low pressure and high pressure systems, it can be used for pressure regulation and discharge of regional pressure regulating or industrial gas supply stations.According to the flow rate of the pressure regulating station, the customer chooses the size of the regulator port.

Operating temperature………………………

Seal material

rubber

Body material

Cast steel

Internal parts material

Stainless steel, carbon steel

installation

Precautions

- 20~+60℃

Type of applicable gas:

?natural gas

?Non-corrosive gas

?air

1.

Please read the instructions carefully before using the regulator. Incorrect operation may result in damage to the product or cause a dangerous accident.

2.It must be installed and installed by a professional.

3.After the installation is complete, the entire system should be thoroughly checked and verified.

caveat

?Please turn off the air supply before installation.

?The gas flow direction is consistent with the direction of the inlet and outlet of the regulator body

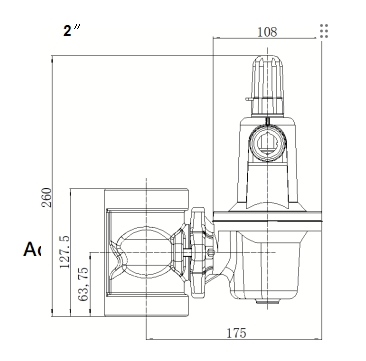

Dimensional chart (mm)

note

Adjustments must be performed by qualified professionals!

|

Threaded connection

|

?Note that no debris can enter the regulator during installation.

?The gas flow direction is consistent with the direction of the inlet and outlet of the pressure regulator valve body.

?Use a reliable threaded sealing material connection, the thread should meet the standard, and the connecting pipe should be cleaned.

?Do not over-tighten the connecting tube or connector to avoid over-deformation or damage.

?When tightening the connecting pipe, it is not allowed to use the parts on the pressure regulator as the force bar, but use a suitable wrench to force the joint of the pressure regulator.

caveat

Seal leak detection after installation

Spray the leak detection fluid evenly at the inlet and outlet connections.

Carefully observe if bubbles are present. If bubbles are found at the joint, you will need to reinstall or replace the regulator.

Final installation check

After the adjustment is completed, run the device for several cycles and check that the device is functioning properly.

Copyright© 1995 - 2009 Egypt.com Inc. All rights reserved